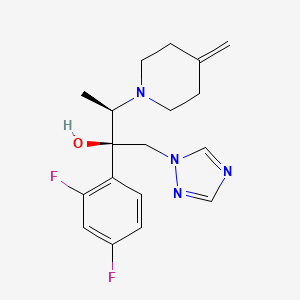

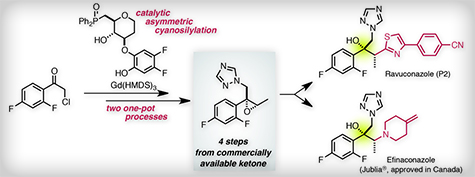

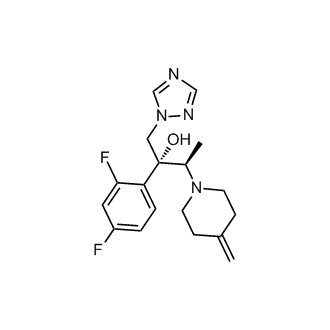

Efinaconazole

(2R,3R)-2-(2,4-Difluorophenyl)-3-(4-methylene-1-piperidinyl)-1-(1H-1,2,4-triazol-1-yl)-2-butanol

(2R, 3R) -2 – (2,4 – difluorophenyl) -3 – (4 – methylene-piperidin-1 – yl) -1 – (1H-1, 2,4 – triazol-1 – yl) butan-2 – manufacture ol (KP-103)

Efinaconazole is a triazole antifungal. It is approved for use in Canada as 10% topical solution for the treatment of onychomycosis (fungal infection of the nail).[1][2] Efinaconazole acts as a 14α-demethylase inhibitor.[3]

| Identifiers | |

|---|---|

| CAS number | 164650-44-6 |

| PubChem | CID 489181 |

| ChemSpider | 428538 |

| Chemical data | |

| Formula | C18H22F2N4O |

| Mol. mass | 348.39 g/mol |

SEE AT

LAVAL, Quebec, June 9, 2014 /PRNewswire/ — Valeant Pharmaceuticals International, Inc. (NYSE: VRX) (TSX: VRX) today announced that that its wholly owned subsidiary, Valeant Pharmaceuticals North America LLC, received notice that the U.S. Food and Drug Administration (FDA) has approved the New Drug Application (NDA) for Jublia® (efinaconazole 10% topical solution), the first topical triazole approved for the treatment of onychomycosis of the toenails

The method for obtaining the amino alcohol by ring-opening addition reaction of the amine to the epoxide, in general, using a large excess of amine, and is performed for a long time at a high temperature. In the conventional method, in order to use the amine of the large excess of byproducts is large and requires a recovery step of an amine, also in terms of production costs, it is desirable as a production method on an industrial scale if the amine is expensive no. In order to increase the reactivity of the reaction, the reaction using a Lewis acid have been proposed, also, difficult to use industrially Lewis acid to be used is unstable or expensive, perchlorate, etc., are those toxic-risk is less secure high, there is a problem such as needing attention in use (Non-Patent Documents 1 and 2). It is also reported that could be the use of lithium bromide, to enhance the reactivity under solvent-free conditions at room temperature (Non-Patent Document 3). It is believed that since the liquid at normal temperature and epoxides, amines are used, the method reported in the literature, was achieved by reaction at a high concentration under solvent-free conditions starting material. Thus, a solid at room temperature and can not be applied to epoxides and amines, particularly high melting point.

On the other hand, as described in Patent Document 1, formula 1 compound is produced by ring-opening addition reaction of the amine to the epoxide. In this production process, as the epoxide (2R, 3S) -2 – (2,4 – difluorophenyl) -3 – methyl -2 – [(1H-1, 2,4 - triazol-1 - yl) methyl] oxirane and ( used that methylene piperidine (hereinafter, abbreviated as “4-MP” also) some – is used will hereinafter be abbreviated as “epoxy triazole” also) some, 4 as the amine. In this manufacturing process, it has the disadvantage for heating under reflux for a long time by using the 4-MP solution in large excess in the ring-opening addition reaction, and it is necessary to by-products are produced much in the reaction step to remove them. Furthermore, 4 – methylene-piperidine is prepared by the method described in Patent Document 2, but the purity is low because it is obtained in an aqueous solution, and also affects the reactivity when the distillation isolation there is a problem of impurities by heat generated.

WO 94/26734 pamphlet WO 97/11939 pamphlet

Synthesis, 2004, No.10, pp 1563-1565 J. Org. Chem., 2007, vol. 72, pp 3713-3722 Eur. J. Org. Chem., 2004, No.17, pp 3597-3600

The purpose of the present invention, (2R, 3S) -2 – to oxirane (2,4 – difluorophenyl) -3 – methyl-2 – [methyl-(yl 1H-1, 2,4 - - -1 triazole)] that without using methylene piperidine may yield a compound of Formula 1 under mild conditions to provide a manufacturing method with a reduced formation of by-product – 4 large excess of ring-opening addition reaction of methylene piperidine – 4 some.

As a result of intensive investigations, 4 the present inventors found that – if the acid addition salt of methylene-piperidine, 4 – impurities incorporated in the acquisition phase of the methylene piperidine has been removed, will be isolated as a solid high purity It can, therefore, four of the starting raw material in the ring-opening addition reaction of the amine to epoxy triazole – and that is able to increase the purity of methylene piperidine, the reaction solvent, the ring-opening addition reaction of amines to the epoxy triazole medium, is performed in the presence of hydroxides of alkali metals or alkaline earth metals in particular, 4 – there is no need to use excess methylene piperidine, high yield, by-products and a compound of Formula 1 under mild conditions to discover that it can be produced by reducing things, and have completed the present invention.

I will explain in detail the methods of the present invention are described below.

As indicated by the following reaction formula, the present invention, (2R, 3S) -2 – (2,4 – difluorophenyl) -3 – methyl -2 – [(1H-1, 2,4 - triazol - hydrate thereof or a hydroxide of an alkali metal or alkaline earth metal is selected from the group the reaction solvent, consisting of strontium lithium, sodium, and calcium, and a methylene piperidine acid addition salt and 4 - yl) methyl] oxirane including the presence of a, is reacted relates to a manufacturing method of the formula (1) compound.

(Wherein HX represents an acid addition salt of the acid)

Starting material of the process of the present invention

It can be also performed by using a starting compound of any amount ranging ton level from the g level, the method of the present invention may be determined the amount of solvent depending on the amount of the starting compound used.

(2R, 3S) -2 – (2,4 – difluorophenyl) -3 – methyl -2 – [(1H-1, 2,4 - -1 triazole - yl) methyl] oxirane, JP 2-191262 issue It can be obtained by methods described in the Gazette.

4 – is represented by the following formula methylenepiperidine acid addition salts:

Wherein an acid of the acid addition salts with HX, 4 – The acid forming the methylene piperidine acid addition salts may, for example, hydrochloric, hydrobromic, if an acid that forms a salt with an amine is basically inorganic acid acid, hydroiodic acid, sulfuric acid, nitric acid, phosphoric acid, boric acid, chloric acid, carbonic acid, etc.; formic acid, acetic acid, trifluoroacetic acid, propionic acid, oxalic acid, methanesulfonic acid, benzenesulfonic acid, p – organic acids such as toluenesulfonic acid and the like, but is not limited thereto. Hydrochloric acid, hydrobromic acid, hydroiodic acid, nitric acid, trifluoroacetic acid and the like, more preferably, preferred examples of the acid is a hydroiodic acid or hydrobromic acid.

4 – methylene-piperidine acid addition salt, 4 – can be obtained by reacting a conventional manner with an acid corresponding to the acid addition salt with methylene piperidine.

Here, the 4 – methylenepiperidine may be preferable in terms of production on an industrial scale, prepared by the method described in WO 97/11939 pamphlet. 4 is manufactured here – methylene-piperidine, and also are obtained in the form of an aqueous solution, impurities produced by heat during the distillation isolation is included, according to the manufacturing method described below, 4 – methylene-piperidine the impurities are removed, acid addition salts can be isolated as a solid high purity.

That is, 4 – preferred method of methylenepiperidine acid addition salts, the following steps:

(1) 4 – reacting with an acid corresponding to the acid addition salt, a solution of methylene-piperidine, and (2) the solvent is evaporated as necessary, washed suspension crystallization or a product obtained , it is a method comprising the step of purifying.

Here, 4 (1) Step – A solution of methylene piperidine solution in a mixed solvent of alcohol or water and aqueous alcohol solution or (such as methanol), and the like. 0.9-1.0 equivalents is preferably used amount of the methylene piperidine – 4 of the acid corresponding to the acid addition salt. Reaction conditions (1) is carried out at room temperature from 0 ℃, the reaction time is several hours 15 minutes.

After the step (1), if necessary, by conventional methods, for example, under reduced pressure, the temperature is carried out by heating from room temperature solvent was evaporated. In the case of decreasing the water content of the reaction system, for example, by azeotropic toluene or use of the desiccant.

How to purify washed suspension or crystallization in step (2) The method of cleaning is suspended in a solvent crystals or recrystallized after being dissolved in a solvent, obtained by filtration, or distilling off the solvent I may be mentioned.

The acid addition salts, conditions of the production method is different, for example, after the reaction of step (1), the solvent was evaporated, the case of hydrochloride and hydrobromide and acetone crystals was then obtained After washing the suspension and filtered. For p-toluenesulfonate, After the reaction of step (1), the solvent was evaporated, and dissolved in ethyl acetate (10:1) / isopropanol mixture and the residue is recrystallized. For nitrate hydroiodide, and trifluoroacetic acid salt, after the reaction of step (1) to dryness by distilling off the solvent, washed and suspended by addition of diisopropyl ether to the residue.

Reaction conditions of the process of the present invention

4 – triazole for the epoxy, the amount of methylene piperidine acid addition salt is 1 to 5 equivalents, preferably 1 to 1.5 equivalents.

As the hydroxide of alkali metal or alkaline earth metal in the reaction of the present invention, a hydrate thereof or strontium hydroxide lithium hydroxide, sodium hydroxide, calcium hydroxide and the like. More preferably, lithium hydroxide, a hydrate thereof or calcium hydroxide, more preferably a hydrate thereof or a lithium hydroxide.

The amount of the hydroxide of alkaline earth metals varies depending on the basicity and the type of compound used or the alkali metals, 4 – for methylenepiperidine acid addition salt is 1 to 5 equivalents usually preferably is 1 to 1.5 equivalents.

Production Example 1

Methanol / water mixture methylene piperidine (4-MP) – 4 obtained by the method described in the manufacture WO 97/11939 pamphlet methylene piperidine hydrobromide salt of (4-MP · HBr) – 4 was cooled by stirring in an ice bath under a solution 0.8M 500mL (0.4mol). Thereafter, the solution is added in several portions (0.36mol) 48% hydrobromic acid 61.3g, followed by stirring for 1 hour in an ice bath. Thereafter, to precipitate white crystals by evaporating the solvent by heating under reduced pressure. Subsequently, we conducted two times operation for azeotropic water by distilling off the solvent by heating under reduced pressure and toluene was added to 50mL, and added acetone 192mL, was 2 hours under stirring ice bath. Thereafter, The crystals are filtered, washed crystals with 60mL (cooled in an ice bath) of acetone, 4-MP · HBr58g as colorless crystals (yield: 90%) After air-drying at room temperature, for 12 hours and dried under reduced pressure at 40 ℃ I got.

1 H-NMR (500MHz, CDCl 3)

δ: 2.62 (4H, t, J = 6.09 Hz), 3.26 (4H, t, J = 6.09 Hz), 4.90 (2H, s), 9.18 (1H, br).

Melting point (DSC): 147 ~ 147.9 ℃

Production Example 2

Water removal operation (4-MP) methylene piperidine – 4 obtained by the method described in the manufacture WO 97/11939 pamphlet methylene piperidine p-toluenesulfonic acid salt of (4-MP · PTSA) – 4 isopropanol (9.7g, 0.1mol) of (IPA) in (50mL) solution, 4-MP, which is subjected to, the resulting p-toluenesulfonic acid monohydrate (PTSA · H 2 O) (18.1g, 0.095mol) / was added (80mL) IPA, (weak exothermic) after which the mixture was stirred for 30 minutes at room temperature, evaporated under reduced pressure IPA, and was heated and dissolved in (250mL) with ethyl acetate / IPA mixture = 10:1 residue. After cooling to room temperature and allowed to stand for 20 hours at 0 ~ 5 ℃, filtered washing the precipitated crystals were obtained (91.2% yield) 4-MP · PTSA 23.34g of white crystals to dry.

1 H-NMR (400MHz, DMSO-d 6)

δ: 2.29 (3H, s), 2.35 (4H, t, J = 6.4 Hz), 3.08 (4H, t, J = 6.4 Hz), 4.85 (2H, s), 7.13 (2H, d, J = 8.2 Hz ), 7.49 (2H, d, J = 8.2 Hz), 8.58 (2H, brs).

Production Example 3

4 obtained by the method described in the manufacture WO 97/11939 pamphlet methylene piperidine hydrochloride (4-MP · HCl) – - 4 subjected to moisture removal operation methylene piperidine (4-MP), obtained was cooled by stirring in an ice bath under (4.12mol) 4-MP 400g that is. Thereafter, the solution was added concentrated hydrochloric acid and 350mL (4.08mmol), and the mixture was stirred in an ice bath. After concentration under reduced pressure was performed 3 times operation for azeotropic water and concentrated under reduced pressure and toluene was added to 300mL. The washed suspension under ice-cooling and addition of acetone 300mL. The filtered crystals were washed with acetone crystals, 4 and dried under reduced pressure at room temperature – was obtained (46% yield) methylene-piperidine hydrochloride (4-MP · HCl) 336.8g.

1 H-NMR (500MHz, CDCl 3)

δ: 2.58 (4H, t, J = 6.1Hz), 3.22 (4H, t, J = 6.1Hz), 4.89 (2H, s), 9.70 (1H, br s).

Preparation Example 4

Methanol / water mixture methylene piperidine (4-MP) – 4 obtained by the method described in the manufacture WO 97/11939 pamphlet methylene piperidine hydriodic acid salt of (4-MP · HI) – 4 was cooled by stirring in an ice bath under a solution 0.66M 20mL (13.19mmol). Thereafter, the solution was added 57% hydroiodic acid and 2.66g (11.84mmol), and the mixture was stirred for 15 minutes in an ice bath. After concentrated under reduced pressure, to precipitate a white solid by performing twice the operation for azeotropic water and concentrated under reduced pressure and toluene was added to 1.6mL. The washed suspension for 1 hour at room temperature by addition of diisopropyl ether 6mL. Thereafter, The crystals are filtered, washed and crystallized with diisopropyl ether, 4 and dried under reduced pressure at room temperature – was obtained (90% yield) methylene piperidine hydroiodide (4-MP · HI) 2.66g.

1 H-NMR (500MHz, CDCl 3)

δ: 2.66 (4H, t, J = 6.1Hz), 3.31-3.33 (4H, m), 4.91 (2H, s), 8.34 (1H, br s).

Preparation Example 5

The reaction was carried out similarly to the above method by using trifluoroacetic acid (TFA) 1.35g and (11.87mmol) in place of hydriodic acid production 57% methylene piperidine trifluoroacetate salt of (4-MP · TFA), – 4 I got a (92% yield) methylene piperidine trifluoroacetate (4-MP · TFA) 2.55g – 4.

1 H-NMR (500MHz, CDCl 3)

δ: 2.50 (4H, t, J = 6.1Hz), 3.16 (4H, t, J = 6.1Hz), 4.89 (2H, s), 9.52 (1H, br s).

Preparation Example 6

The reaction was carried out in the same manner as the above-described method using 69% nitric acid 1.08g the (11.87mmol) instead of hydroiodic acid production 57% methylene piperidine nitrate (4-MP · HNO 3), 4 – - 4 methylenepiperidine nitrate I got a (89% yield) (4-MP · HNO 3) 1.87g.

1 H-NMR (500MHz, CDCl 3)

δ: 2.53 (4H, t, J = 6.1Hz), 3.28 (4H, t, J = 6.1Hz), 4.89 (2H, s), 8.85 (1H, br s).

Example 1

(2R, 3R) -2 – (2,4 – difluorophenyl) -3 – (4 – methylene-piperidin-1 – yl) -1 – (1H-1, 2,4 – triazol-1 – yl) butan-2 – manufacture ol (KP-103)

Was stirred while addition of acetonitrile 80mL, lithium hydroxide 2.859g methylene piperidine hydrobromide (4-MP · HBr) 21.26g and (119.4mmol) and (119.4mmol) – 4 obtained in Production Example 1. Then, (2R, 3S) -2 – (2,4 – difluorophenyl) -3 – methyl -2 – [(1H-1, 2,4 - triazol-1 - yl) methyl] oxirane and 20g (79.6mmol) was added, and the mixture was heated under reflux for 14 hours at (external temperature 100 ℃) oil bath. After completion of the reaction, to precipitate the crystals by the addition of ethanol and distilled water to the reaction solution. Thereafter, the crystals were filtered, washed with ethanol / water mixture 40mL, and naturally dried at room temperature for 12 hours and dried under reduced pressure at 40 ℃, KP-103 24.2g light yellow 87.3% (yield, HPLC purity 95.3 % I got).

1 H-NMR (500MHz, CDCl 3)

δ: 0.96 (3H, dd, J = 2.68, 7.08 Hz), 2.13-2.26 (4H, m), 2.35 (2H, br), 2.70 (2H, br) ,2.90-2 .94 (1H, q, J = 7.08 Hz), 4.64 (2H, s), 4.82 (1H, dd, J = 0.73, 14.39 Hz), 4.87 (1H, dd, J = 0.73, 14.39 Hz), 5.45 (1H, s), 6.72-6.81 (2H , m), 7.51 (1H, dt, J = 6.59, 9.03 Hz), 7.78 (1H, s),

8.02 (1H, s).

FAB-MS m / z: 349 [M + H] +

:86-89 ℃ melting point

Optical rotation: [α] D 25 -87 ~ -91 ° (C = 1.0, methanol)

Example 2

Epoxy triazole 0.50g (1.99mmol), 4 – in addition to acetonitrile 2mL lithium hydroxide 0.07g methylene piperidine hydrobromide (4-MP · HBr) 0.53g and (2.98mmol) and (2.96mmol), oil bath ( I was heated under reflux for 14 hours at an external temperature of 100 ℃). After the solvent was evaporated under reduced pressure of the reaction solution obtained, the solution was separated by the addition of ethyl acetate and water to the residue. The organic layer was concentrated under reduced pressure and purified by silica gel column chromatography (1:1) hexane / ethyl acetate solvent, to give (86% yield) KP-103 0.59g.

Example 3

The reaction was carried out in the same manner as in Example 2 using the calcium hydroxide 0.22g (2.97mmol) instead of lithium hydroxide, to give (82% yield) KP-103 0.57g.

Example 4

Was performed for 19 hours and the reaction in the same manner as in Example 2 using strontium hydroxide 0.36g a (2.98mmol) in place of lithium hydroxide, to give (68% yield) KP-103 0.47g.

Example 5

Was added 2mL of acetonitrile lithium hydroxide monohydrate 0.13g methylene piperidine hydrobromide (4-MP · HBr) 0.53g and (2.98mmol) and (2.96mmol) – epoxy-triazole 0.50g (1.99mmol), 4 , I was heated under reflux for 14 hours at (external temperature of 100 ℃) oil bath. Was determined to (relative area percentage of KP-103) reaction rate by HPLC measurements by sampling the reaction mixture, it was confirmed the formation of KP-103 at 81% response rate.

Example 6

The reaction was carried out in the same manner as in Example 2 using cyclopentyl methyl ether (CPME) 2mL instead of acetonitrile, to give (91% yield) KP-103 0.63g.

Example 7

1,2 instead of acetonitrile – The reaction was carried out in the same manner as in Example 2 using dimethoxyethane (DME) 2mL, was obtained (79% yield) KP-103 0.55g.

Example 8

1 in place of acetonitrile – The reaction was carried out in the same manner as in Example 2 using butanol 2mL, was obtained (72% yield) KP-103 0.59g.

Example 9

The reaction was carried out in the same manner as in Example 2 using isopropanol 2mL instead of acetonitrile, to give (86% yield) KP-103 0.50g.

Example 10

Methyl – 2 – 4 instead of acetonitrile reaction was carried out in the same manner as in Example 2 using the pentanone (MIBK) 2mL, to give (88% yield) KP-103 0.61g.

Example 11

Example Using methylene piperidine hydrochloride (4-MP · HCl) 0.40g and (2.99mmol) – 4 obtained in Production Example 3 in place of methylene piperidine hydrobromide salt of (4-MP · HBr) – 4 The reaction was carried out in the same manner as 2, was obtained (67% yield) KP-103 0.47g.

Example 12

Using methylene piperidine hydroiodide (4-MP · HI) 0.67g and (2.99mmol) – 4 obtained in Production Example 4 in place of methylene piperidine hydrobromide salt of (4-MP · HBr) – 4 The reaction was carried out in the same manner as in Example 2 upgrade does not give (90% yield) KP-103 0.62g.

Example 13

Using methylene piperidine trifluoroacetate (4-MP · TFA) 0.63g and (2.98mmol) – 4 obtained in Production Example 5 in place of methylene piperidine hydrobromide salt of (4-MP · HBr) – 4 The reaction was carried out in the same manner as in Example 2, was obtained (78% yield) KP-103 0.54g.

Example 14

Example Using methylenepiperidine nitrate (4-MP · HNO 3) 0.48g and (3.00mmol) – 4 obtained in Production Example 6 in place of methylene piperidine hydrobromide salt of (4-MP · HBr) – 4 The reaction was carried out in the same manner as 2, was obtained (71% yield) KP-103 0.49g.

Example 15

Methylenepiperidine hydroiodic acid – 4 obtained in Production Example 4 in place of methylene piperidine hydrobromide salt of (4-MP · HBr) – Sodium hydroxide 0.12g (2.98mmol), 4 instead of lithium hydroxide was performed 18 hours and the reaction in the same manner as in Example 2 using salt (4-MP · HI) 0.67g and (2.99mmol), to give (73% yield) KP-103 0.51g.

Conventional methods for producing formula 1 compound of the starting material 4 – impurity contamination at the acquisition stage of methylene piperidine, and by-products to be produced during the manufacture of the formula 1 compound was a problem. In the method of the present invention, as a starting material of the production method of the formula 1 compound, 4 – by making the acid addition salt of methylene-piperidine, 4 – impurities incorporated in the acquisition phase of the methylene piperidine has been removed, high purity it is possible to use a solid. In the method of the present invention, since the ring-opening addition of the amine to epoxy triazole is promoted, 4 – there is no need to use excess methylene piperidine, high yield, and by-products of the compound of Formula 1 under mild conditions It can be produced by reducing compound. Therefore, by the method of the present invention to produce an industrial scale formula 1 compound became possible.

| Cited Patent | Filing date | Publication date | Applicant | Title |

|---|---|---|---|---|

| WO1994026734A1 | May 2, 1994 | Nov 24, 1994 | Tadashi Arika | Azolylamine derivative |

| WO1997011939A1 | Sep 26, 1996 | Apr 3, 1997 | Kaken Pharma Co Ltd | Process for the preparation of 4-methylenepiperidines |

| JPH02191262A | Title not available |

| Reference | ||

|---|---|---|

| 1 | EUR. J. ORG. CHEM. 2004, pages 3597 – 3600 | |

| 2 | J. ORG. CHEM. vol. 72, 2007, pages 3713 – 3722 | |

| 3 | * | MIMURA, MITSUO ET AL.: ‘Synthesis and evaluation of (piperidinomethylene)bis (phosphonic acid) derivatives as anti- osteoporosis agents‘ CHEMICAL & PHARMACEUTICAL BULLETIN vol. 41, no. 11, 1993, pages 1971 – 1986 |

| 4 | * | OGURA, HIRONOBU ET AL.: ‘Synthesis and antifungal activities of (2R,3R)-2-aryl-1-azolyl-3-(substituted amino)-2-butanol derivatives as topical antifungal agents‘ CHEMICAL & PHARMACEUTICAL BULLETIN vol. 47, no. 10, 1999, pages 1417 – 1425, XP002296880 |

| 5 | SYNTHESIS 2004, pages 1563 – 1565 | |

|

10-6-1999

|

Azolylamine derivative

|

|

|

2-11-1998

|

Azolylamine derivative

|

|

|

12-18-1997

|

AZOLYLAMINE DERIVATIVE

|

|

|

4-16-1997

|

Azolylamine derivative

|

References

- Patel T, Dhillon S (Nov 2013). “Efinaconazole: first global approval”. Drugs 73 (17): 1977–1983. doi:10.1007/s40265-013-0152-x. PMID 24249649.

- Tschen EH, Bucko AD, Oizumi N, Kawabata H, Olin JT, Pillai R (Feb 2013). “Efinaconazole solution in the treatment of toenail onychomycosis: a phase 2, multicenter, randomized, double-blind study”. J Drugs Dermatol 12 (2): 186–192. PMID 23377392.

- Tatsumi Y, Nagashima M, Shibanushi T, et al. (May 2013). “Mechanism of action of efinaconazole, a novel triazole antifungal agent”. Antimicrob Agents Chemother 57 (5): 2405–2509.

Filed under: FDA 2014 Tagged: efinaconazole